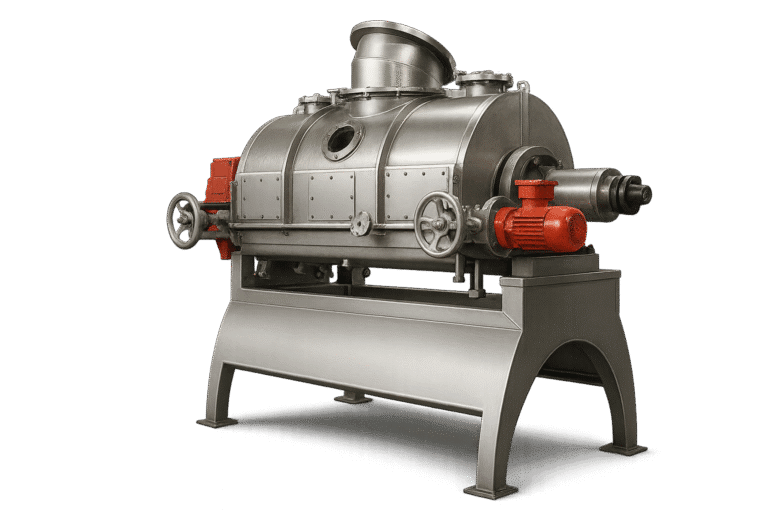

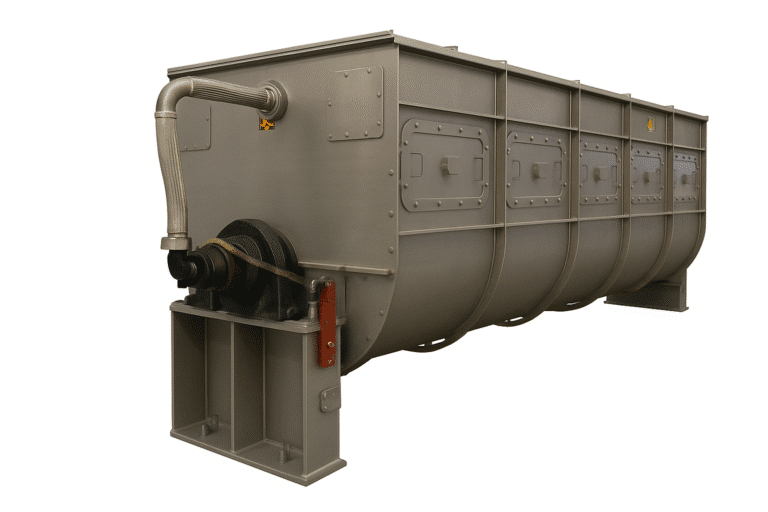

With decades of continuous development and real-world application, the tubular dryer has become a benchmark in quality, sustainability, and process efficiency, a machine that truly sets itself apart.

What makes the tubular dryer unique?

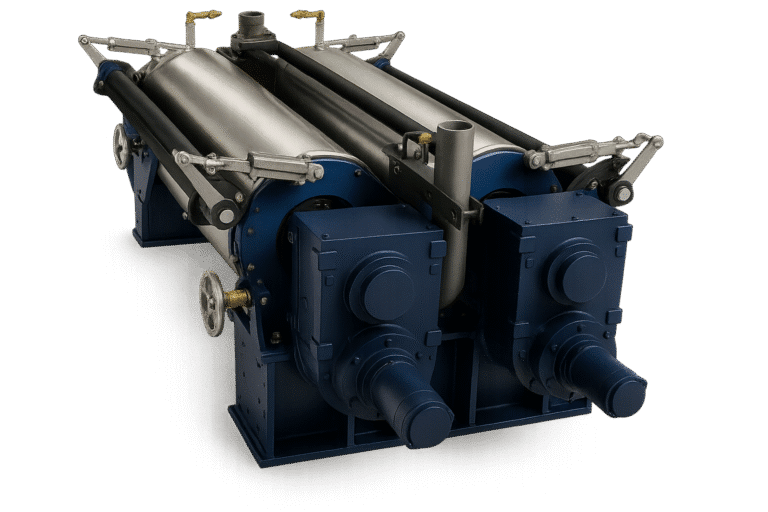

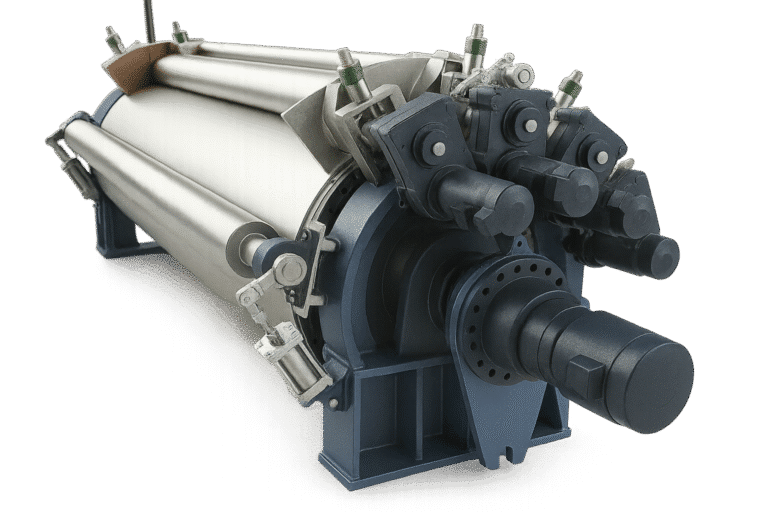

The tubular dryer is an indirect-contact dryer, using dry, saturated steam as its heating medium. A rotating bundle of steam-heated tubes gently conveys and dries the product inside a stationary casing, ensuring uniform heat transfer and controlled moisture removal.

Because the product never comes into direct contact with hot air or combustion gases, the process is clean, safe, and highly controllable.

Key advantages

- Continuous operation – ideal for high-capacity, 24/7 production

- Gentle drying – preserves product quality, structure, and functionality

- Minimal dust formation – thanks to indirect heating and low air volumes

- High operational safety – reduced explosion risk compared to hot-air dryers

- Low maintenance design – robust construction with long service life

Energy efficiency

at its core

Energy efficiency is one of the strongest advantages of the tubular dryer and a key reason it has remained relevant for nearly a century.

- Steam-based heating allows efficient energy transfer with minimal losses

- Condensate recovery returns energy back to the boiler system

- Very low sweep-air requirements reduce fan energy and dust filtration needs

- Stable thermal conditions prevent unnecessary over-drying

Compared to conventional hot-air dryers, tubular dryers deliver significantly lower energy consumption per kilogram of evaporated moisture, making them a future-proof solution in an increasingly energy-conscious world.

Efficiency isn’t an add-on — it’s built into the design.

Unmatched expertise

The tubular dryer is the machine where Tummers Simon Dryers Technology holds the deepest knowledge. From food and starch to confectionery, metal powders, and by-products. We’ve seen, tested, and optimised countless applications.

With over 100 years of drying experience and nearly a century of tubular dryer development, we confidently say: there is no competing technology that matches this combination of quality, durability, safety, and efficiency.

See it live

at ProSweets Cologne

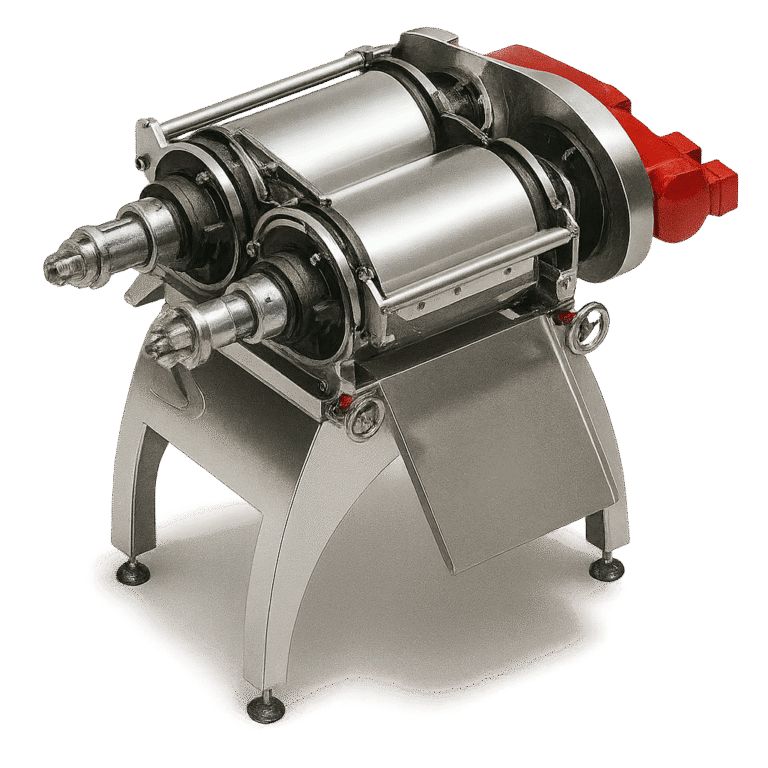

This year, we’re proud to show the laboratory-scale Tubular Dryer at ProSweets Cologne, giving visitors a close look at the technology.

📍 ProSweets Cologne

📍 Hall 10.1 – Stand B058

Our colleagues Patrick Vosse and Chris Ellis will be present at the stand to answer your questions, discuss applications, and explore how tubular drying can improve your process.

Build for today. Ready for tomorrow.

From its early days in the 1930s to today’s energy-efficient, data-driven production environments, the tubular dryer has evolved, without ever losing its core strength.

It’s a machine built to last.

A machine built to perform.

And a machine that continues to define the future of sustainable drying.