Smarter. Cleaner. More connected; the future of drying and processing starts here.

At Tummers Simon Dryers Technology, we don’t just build machines, we build intelligent systems.

Our Tummers Smart Solutions combine decades of mechanical expertise with the latest digital innovations, preparing your production for a smarter, more sustainable generation.

Through strong partnerships and forward-thinking technology, we’re shaping the factories of tomorrow where efficiency, reliability, and insight come together seamlessly.

Step into the future

“Step into the Future” was our first move towards Industry 4.0, the next phase of intelligent manufacturing.

Together with partners such as Solutherm, Polysense, Siemens, and Callens, we’ve developed systems that make production lines cleaner, safer, and more connected.

Our vision is simple: every Tummers machine should think, learn, and optimize, just like the people who operate it.

The backbone of Smart Solutions

Our innovation roadmap is currently built around two core technologies:

E²E – Emission-to-Energy

With E²E (Emission-to-Energy), Tummers introduces a smart technology that turns steam emissions into reusable energy, moving closer to a zero-emission production line.

Originally developed for potato processing, this innovation captures, condenses, and reuses steam and heat like never before, saving massive amounts of energy and reducing environmental impact.

- Hygienic and compact design

- Significant energy savings

- Energy recovery and reuse

- Seamless integration with existing systems

E²E transforms waste into power; a true step toward sustainable production.

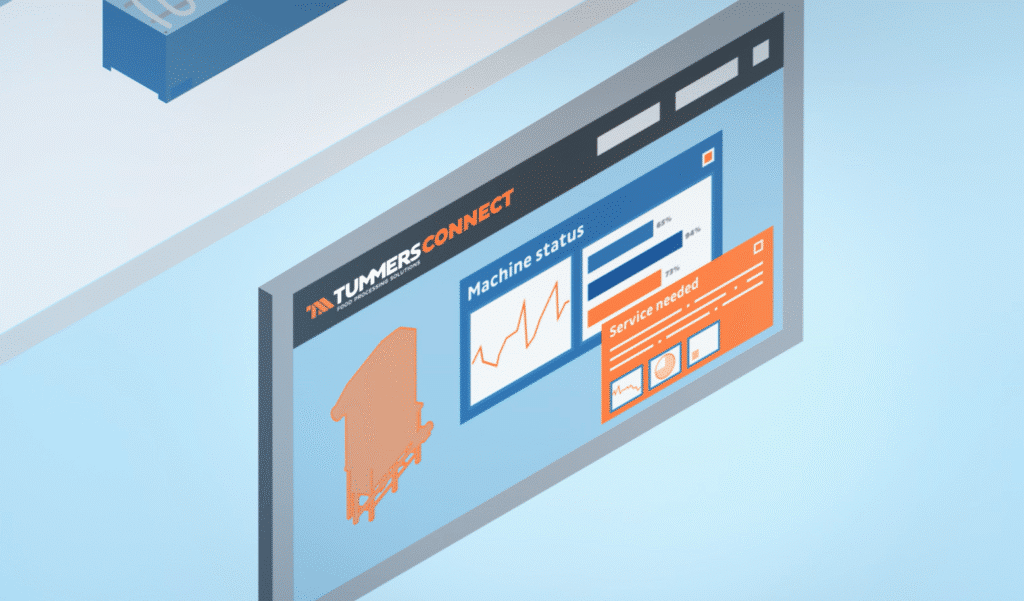

Tummers Connect

Your digital gateway to the factory floor, anywhere, anytime.

With Tummers Connect, operators and managers can monitor performance remotely, access maintenance data, and receive predictive alerts before issues arise.

- Predictive maintenance – identify wear and performance changes early

- Remote monitoring – track line performance across multiple sites

- Energy and performance dashboard

- Automatic adjustments – adapt process parameters to product variation

- Instant documentation – manuals, service data, and performance reports available at the touch of a button

Innovation through collaboration

Innovation happens when expertise meets openness.

By working with trusted technology partners like Siemens, Solutherm, Polysense, and Callens, we ensure that our Smart Solutions combine proven reliability with cutting-edge design.

Together, we’re developing the next generation of process technology:

- Energy-efficient heating and control systems

- Sustainable steam and heat recovery integration

- Real-time product analysis and quality control

- Advanced data architecture for connected manufacturing

Why work with us?

100+ years

experience in drying technology.

Engineered

Machines designed for dust control, energy efficiency, hygiene and clean-label compatibility.

Support

From testing in our lab to installation and after-sales service.

Sustainable

Efficient steam use, minimal waste and high product yield.

They are our digital innovations that combine automation, data, and energy optimisation and helping factories operate more efficiently, sustainably, and intelligently.

Yes. Most Smart Solutions can be retrofitted to existing Tummers or Simon Dryers systems upgrading your current setup for Industry 4.0 compatibility.

- Improved uptime and reduced maintenance costs

- Lower energy consumption

- Better quality consistency

- Real-time process transparency

By analysing production and energy data, Smart Solutions enable heat recovery, process optimisation, and/or emission reduction, all while maintaining product quality.