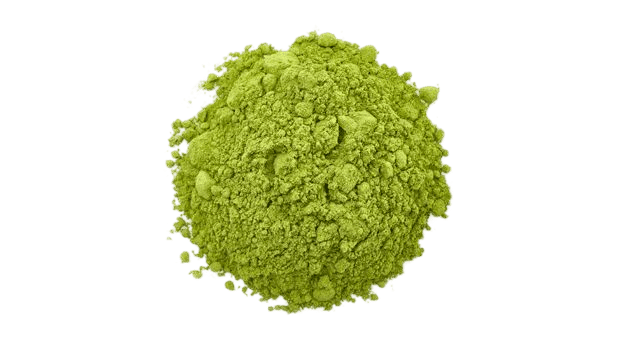

From fresh produce to high-quality powders and flakes; preserving nature’s goodness with innovation.

In the modern food processing industry, converting fruits and vegetables into shelf-stable powders or flakes is more than convenience: it’s about preserving nutritional value, clean labeling and delivering great taste and texture. We specialise in drying industrys that support preservative-free, gluten-free and dairy-free options for your brand.

Ready to discuss your fruit & vegetable application? Our team is here to help.

Why choose our drying technology for fruits & vegetables?

Tailored machine industrys – For example

-

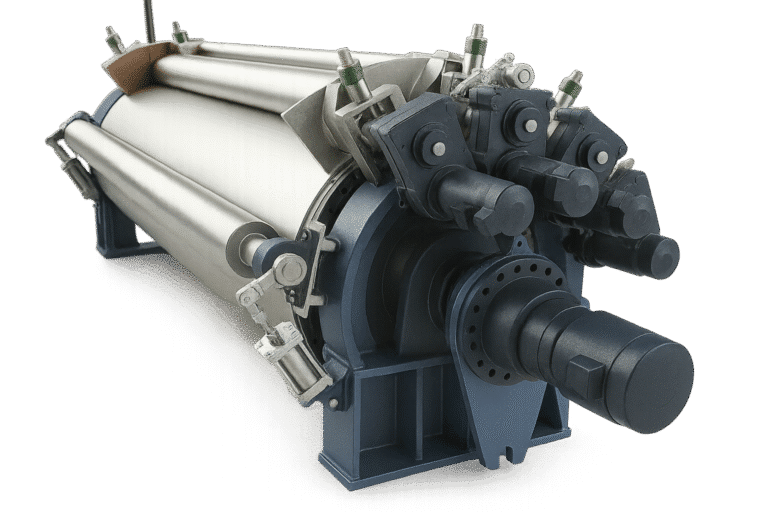

- Use our Single-Drum Dryer for potato-based products, carrot, pineapple, sweet potato, etc.

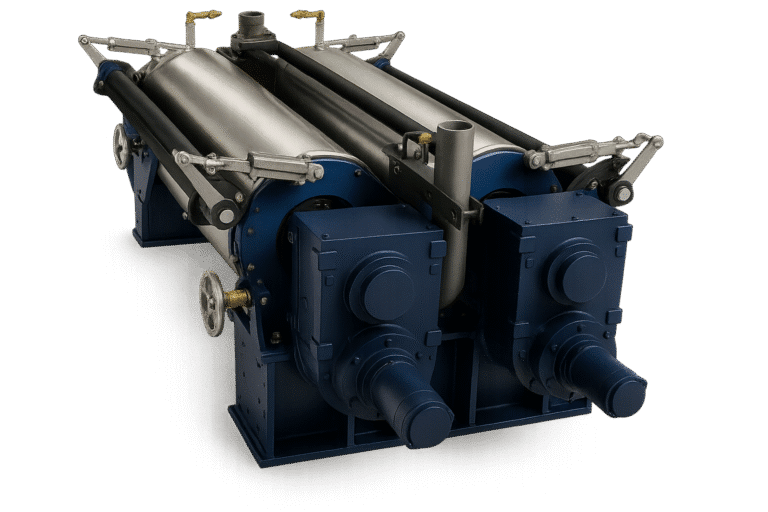

- Use our Double Drum Dryer for banana, tomato, etc.

Each machine is selected to match the material behaviour and desired output.

High nutritional retention

Gentle yet efficient drying preserves vitamins, colour and flavour.

Clean label friendly

We enable powders and flakes that are sugar-free, preservative-free, gluten-free and dairy-free.

Versatile end-formats

Produce finely milled powders or larger flakes depending on your needs.

Lab-to-production support

We have extensive test data and offer laboratory trials to ensure you get the right process before full-scale investment.

How we process your product

1. Feed / preparation – Fruits or vegetables are cleaned, mashed or pulped to suitable consistency.

2. Machine selection & drying –

- For potato mash → our Single-Drum Dryer: a thin layer is applied, moisture evaporated rapidly and product removed as flakes. Our sister at Tummers Food Processing Solutions are the experts when it comes to Potato Processing

- For banana, tomato, pineapple slurries → our Double-Drum Dryer: material introduced between two drums, film thickness adjusted, moisture evaporated from both sides.

3. Product handling – Dried flakes or powders are collected, milled or screened, cooled and packed.

4. R&D & optimization – In our lab we test materials, drying behaviour and final product specs, so you launch with confidence.

Don’t see your specific material listed?

We’ve processed a wide variety of fruit & vegetables; let’s discuss your unique feedstock and test it in our laboratory.

Typical applications

- Potato flakes or powders

- Banana, tomato, pineapple fruit powders

- Carrot, beetroot, sweet potato mash dehydration

- Algae & seaweed powders for nutritional products

- Pet-food / animal feed vegetable flakes & powders

- Custom fruit/veg blends for high value ingredients

Don’t see your specific material listed?

We’ve processed a wide variety of fruit & vegetables; let’s discuss your unique feedstock and test it in our laboratory.

Why work with us?

100+ years

experience in drying technology.

Engineered

Machines designed for dust control, energy efficiency, hygiene and clean-label compatibility.

Support

From testing in our lab to installation and after-sales service.

Sustainable

Efficient steam use, minimal waste and high product yield.

Frequently asked questions

It depends on your material’s moisture content, consistency, desired output (powder or flake) and volume. For example, potato mash suits a single-drum dryer; banana or tomato slurries suit a double-drum dryer. We’ll help you choose.

Yes. We select machine parameters (drum temperature, layer thickness, residence time) carefully to avoid degradation. In our lab we test to ensure the final product remains high quality.

Absolutely. We have extensive test data and offer dedicated laboratory trials to characterise your feedstock, optimise drying parameters and scale-up reliably.

Yes. Our drying industrys are designed to support sugar-free, preservative-free, gluten-free and dairy-free applications. We maintain hygienic design throughout.

Once the material behaviour is proven in our lab, we can scale up and deliver a full production-grade machine in a straightforward process. Our team supports you every step of the way.

Our machines are engineered for efficient heat transfer, minimal waste, and optimised utility usage. We also offer variable speed drives and advanced process controls for further savings.