High-quality drying for the sweets industry; shaping high-clean-label confectionery with precision.

In the world of sweets and confectionery, consistency, safety and ingredient integrity are non-negotiable. We specialise in drying industrys for the confectionery industry, especially for moulding starches, chocolate crumb, gums, jellies, hard candies, chewy candies, crusted candy and more. Our technology supports your goal of natural ingredients, clean label (gluten-free, dairy-free, preservative-free) and high production reliability.

Let’s talk about how drying technology can support your confectionery process.

Why choose our drying technology for confectionery?

Tailored machine industrys

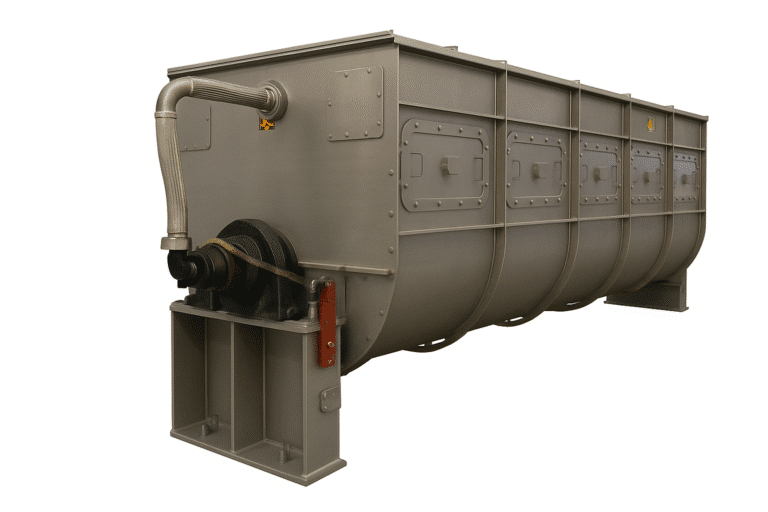

Our Tubular Dryer & Cooler is ideal for moulding starch in confectionery moulding processes.

Our Drum Dryers are ideal for some fruit products, for use as additive-free flavourings and colourings.

Consistent product quality

Gentle, indirect drying ensures controlled moisture and temperature, ideal for sweets that require texture precision.

Clean-label friendly

Our systems support sugar-free, preservative-free, gluten-free and dairy-free formulations.

Wide application

From gels and jellies to hard candies and crusted nuts, we have experience across diverse confectionery formats.

Lab-to-production support

We maintain a fully-equipped laboratory and extensive test data for confectionery applications, ensuring you scale confidently.

How we work for the sweets industry

1. Material preparation – Your sweet base, moulding starch or crumb is pre-treated (cooked, mixed) to the correct consistency.

2. Machine selection & drying –

- For moulding starch → use our tubular dryer & cooler module, configured for minimal dust, low air-sweep and high energy recovery. Check out our Tubular Dryer.

- For fruits and pastes → drum drying techniques to preserve colour, flavour and texture.

3. Product handling – The dried product (powder or granulate) is then cooled, collected and sent on for blending/packaging.

4. R&D & optimization – In our lab we test your drying behaviour, final texture and moisture profile, so you can move into production with confidence.

If you don’t see your exact sweet format listed, don’t worry — we’ve worked with many niche formulations. Contact us to discuss your unique process and arrange a lab trial.

Typical confectionery applications

- Moulding starch drying

- Dust removal

- Clean-label sugar-free confectionery powders

- Gluten-free/dairy-free sweet ingredient drying

If you don’t see your exact sweet format listed, don’t worry — we’ve worked with many niche formulations. Contact us to discuss your unique process and arrange a lab trial.

Why work with us?

100+ years

experience in drying technology.

Engineered

Machines designed for dust control, energy efficiency, hygiene and clean-label compatibility.

Support

From testing in our lab to installation and after-sales service.

Sustainable

Efficient steam use, minimal waste and high product yield.

Frequently asked questions

Our Tubular Dryer & Cooler is typically the best fit: it provides continuous processing, indirect steam heating, minimal dust creation, and optimal temperature/ moisture control for moulding starch in confectionery.

Yes. We adapt the feed thickness, drying temperature, and residence time to ensure sugar-rich pastes dry without caramelisation or texture damage.

Absolutely. We have a dedicated laboratory and trial equipment where your candy or moulding starch can be tested to optimise drying parameters before full-scale purchase.

Yes. Our designs support hygienic operation and are compatible with clean-label ingredient streams. We engineer drying industrys that align with your ingredient and certification goals.

After successful lab testing and proof of process, we support scale-up planning and delivery of production machines. Our team works with you to reduce risk, shorten lead-times and design for your sweet product volumes.

Our systems use steam-based heating and minimal sweep-air, reducing energy loss and dust-filtration costs. For example, the tubular dryer design limits dust creation and uses condensed steam return.