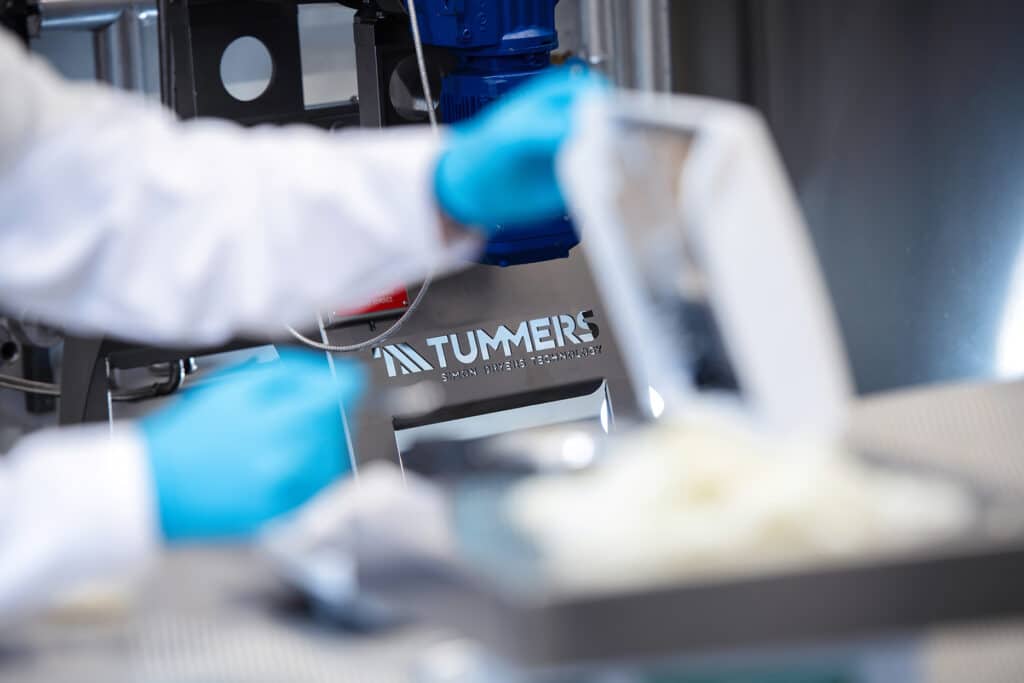

From idea to proof; test, learn and optimise with Tummers Simon Dryers Technology.

In an ever-changing world of new materials and product formulations, testing is essential.

At Tummers Simon Dryers Technology, we offer fully equipped testing facilities to help you determine how your product behaves during drying, flaking, or cooling.

Our goal is simple: to give you clear, reliable data that helps you scale up with confidence.

Ready to test your product? Contact our team to schedule your trial.

Why test with us?

With over 100 years of experience in drying and cooling technology, our laboratory combines historical knowledge with modern precision.

Our testing facilities are staffed by experienced operators, supported by engineers and designers who understand both the science and the process behind every product.

Every test is conducted professionally and hygienically, ensuring safe handling and accurate results — whether it’s food, starch, chemical, or industrial material.

What we can test

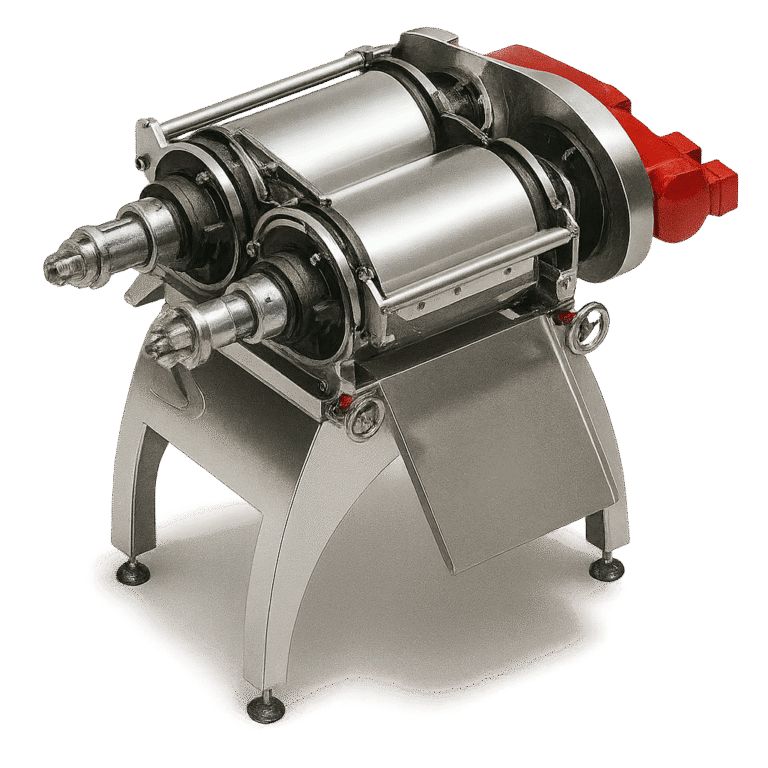

Our facilities include a full range of laboratory-scale drying equipment (not the pilot-scale), enabling us to simulate nearly every production process on a smaller scale.

Available machines in our lab

We also provide measurement equipment for:

-

Viscosity

-

Flake thickness

-

Powder density

-

Moisture content

-

Temperature and humidity logging

Our testing procedure

We follow a structured approach to ensure accuracy and consistency:

- Discuss your objectives – What do you want to achieve?

- Initial material evaluation – Reviewing the product’s properties and safety data.

- Preliminary test – Assessing drying suitability and process potential.

- Full test run – Adjusting speed, temperature, and feed rate for optimal results.

- Data collection & video – Recording parameters and visual footage for analysis.

- Evaluation & feedback – Reviewing results together and recommending next steps.

- Retesting (if required) – Fine-tuning parameters or testing additional samples.

- Final test report – Detailed documentation ready for scale-up.

What you receive

After every test, you’ll get a comprehensive report with:

- Full test data and recorded parameters

- Drying curves and temperature profiles

- Short test video

- Dried or cooled product samples for evaluation

- Expert recommendations for scaling up to production

All data is logged for future reference — helping you fine-tune your process and accelerate development.

All testing is performed confidentially under strict safety and hygiene protocols.

What we require for testing

To ensure accurate and efficient results, we typically need:

- ±25 litres or kilograms of material (depending on product type)

- MSDS (Material Safety Data Sheet)

- Process information (moisture content, handling details, drying goals)

We’ll guide you through every step before your test.

Additional support

Our laboratory is equipped with feed systems, pumps, and a mill sifter for post-test grinding or particle preparation.

Tests are performed under controlled conditions, and all test fees are refunded upon purchase of a production-scale machine.

Want to see your product in action? You’re welcome to attend the test in person or virtually.

Book a test or consultation

FAQ

We can handle liquid, paste, molten, and powder products, including starches, foods, chemicals, waxes, metal powders, and feed ingredients.

We usually require around 25 litres or kilograms of material, depending on its density and form.

Yes! Clients are welcome to attend tests on-site or via video call. You’ll receive both live insights and a recorded video afterward.

A detailed test report, including parameters, drying curves, results, and samples for your own evaluation.

Depending on scheduling, tests can often be planned within a few weeks. Contact us early to reserve a slot.

Absolutely. All materials, results, and data remain strictly confidential and are used only for your project.

Yes. If you proceed to purchase a production-scale machine, your testing charges are fully credited toward the project.