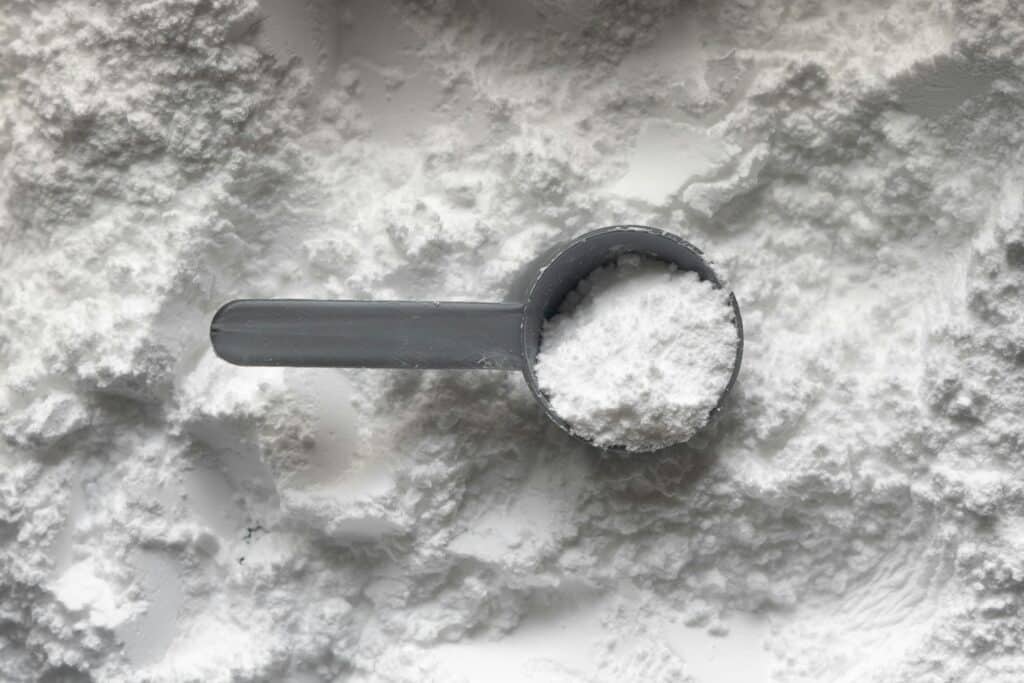

Precision drying for starches; from native to modified, powering food and industrial innovation.

For more than a century, Tummers Simon Dryers Technology has been at the heart of starch processing.

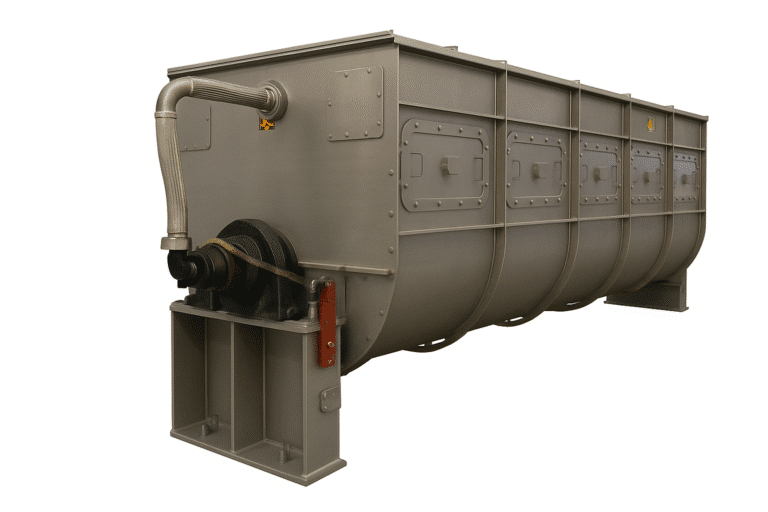

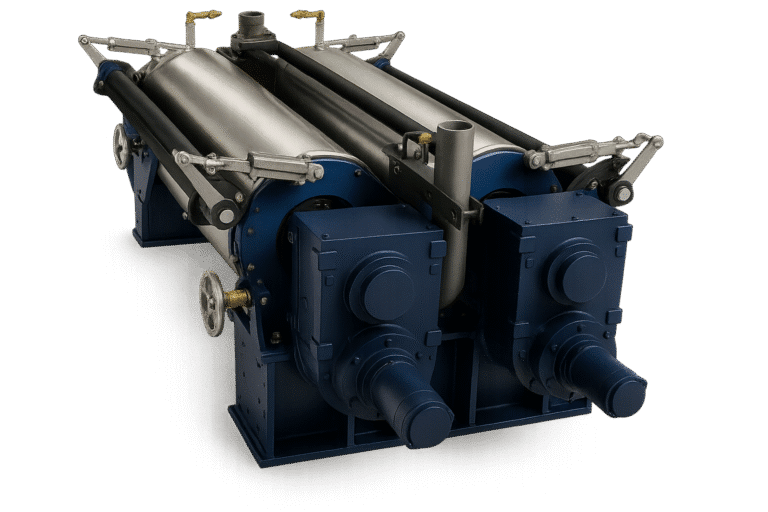

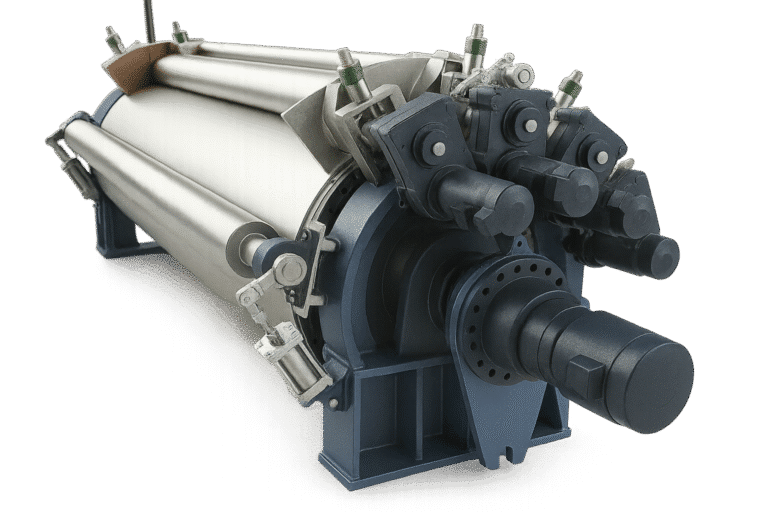

Our Drum Dryers(single and double), and Tubular Dryers deliver high-performance, energy-efficient drying for starches derived from wheat, corn, potatoes, cassava, and many other sources.

Whether you produce food-grade starch, industrial starch, or modified starch derivatives, our technology ensures consistent quality, optimized moisture, and scalable production, built on proven reliability and innovation.

Let’s talk about your starch process — our specialists are ready to help.

Why choose the Simon Dryers for starch drying?

Comprehensive experience

We’ve been designing and building starch dryers for over 100 years.

Tailored machine industrys

-

- Single Drum Dryer → ideal for potato, corn and wheat starches or any other starches, perfect for modified or pre-gelatinized starches.

- Tubular Dryer → for moulding starch or starch by-products with low dust and high energy efficiency.

Optimised product quality

Uniform drying guarantees the desired viscosity, gelatinisation and particle structure.

Food & non-food ready

Built for both ingredient-grade and industrial-grade starch applications.

Lab & pilot testing

Validate process parameters with our dedicated starch test facility before scaling up.

Contact our experts today to optimise your starch drying line.

How it works

- Feed preparation – Starch slurry or modified starch industry is concentrated and pre-filtered.

- Drying –

- On a Drum Dryer, a thin film of starch is applied and dried with precise temperature control, producing powders or flakes.

- In a Tubular Dryer, indirect steam heat removes moisture efficiently with minimal dust formation.

- Cooling & collection – Dried starch is cooled, milled or screened to the required particle size.

- Testing & validation – Our laboratory runs pilot trials to establish the best setup for yield, moisture, and energy efficiency.

Typical applications

- Native starches – potato, corn, wheat, tapioca, rice starch

- Modified starches – pre-gelatinized, oxidized, or hydrolyzed types

- Moulding starch for confectionery

- By-products from starch production (fibres, gluten meal, protein residues)

- Industrial starches for paper, adhesives, textiles and bioplastics

- Food starches for soups, sauces, coatings and instant products

If your starch material isn’t listed here, don’t worry; we’ve tested hundreds of starch types in our facilities.

Book a starch drying trial to analyse your product behaviour and optimise your process.

Performance and sustainability

Our systems combine high thermal efficiency with precise control over moisture and temperature, ensuring stable viscosity, consistent flake formation, and long-term energy savings.

We’re proud to be part of the Tummers Group, a world leader in starch technology and sustainability.

Typical applications

- Native starches – potato, corn, wheat, tapioca, rice starch

- Modified starches – pre-gelatinized, oxidized, or hydrolyzed types

- Moulding starch for confectionery

- By-products from starch production (fibres, gluten meal, protein residues)

- Industrial starches for paper, adhesives, textiles and bioplastics

- Food starches for soups, sauces, coatings and instant products

If your starch material isn’t listed here, don’t worry; we’ve tested hundreds of starch types in our facilities.

Book a starch drying trial to analyse your product behaviour and optimise your process.

Performance and sustainability

Our systems combine high thermal efficiency with precise control over moisture and temperature, ensuring stable viscosity, consistent flake formation, and long-term energy savings.

We’re proud to be part of the Tummers Group, a world leader in starch technology and sustainability.

Why work with us?

100+ years

experience in drying technology.

Engineered

Machines designed for dust control, energy efficiency, hygiene and clean-label compatibility.

Support

From testing in our lab to installation and after-sales service.

Sustainable

Efficient steam use, minimal waste and high product yield.

Frequently asked questions

It depends on your process:

- Single Drum Dryer for native potato, corn or wheat starch, and for pre-gelatinized or modified starches.

- Double Drum Dryer for pre-gelatinized or modified starches.

- Tubular Dryer for moulding starch or starch by-products requiring indirect drying.

Yes. We design machines for food-grade hygiene or industrial robustness, depending on your market and end use.

Our dryers provide precise temperature and residence-time control, delivering consistent drying for viscosity, texture, and rehydration performance.

We’ve successfully processed potato, corn, wheat, tapioca, rice, and cassava starches, along with various modified derivatives and blends.

Absolutely. Our laboratory and pilot dryers allow you to test parameters such as drying rate, temperature, and end-product quality before full-scale production.

Using indirect steam heating, condensate recovery, and low sweep-air systems, our dryers can achieve steam-to-evaporation ratios as low as 1.2:1 a major energy saving compared to hot-air systems.

Yes. We adapt feed mechanisms, film thickness and drum surfaces to suit high-viscosity starches and chemical derivatives.

Yes — gluten meal, fibres, and protein residues can be dried in tubular or drum systems for re-use in feed or bio-applications.