Continuous, energy-efficient drying for metal powders; safe, clean and reliable.

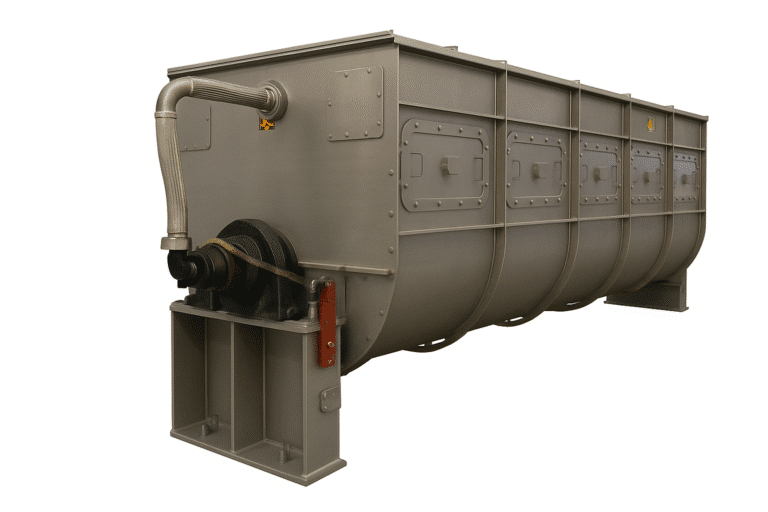

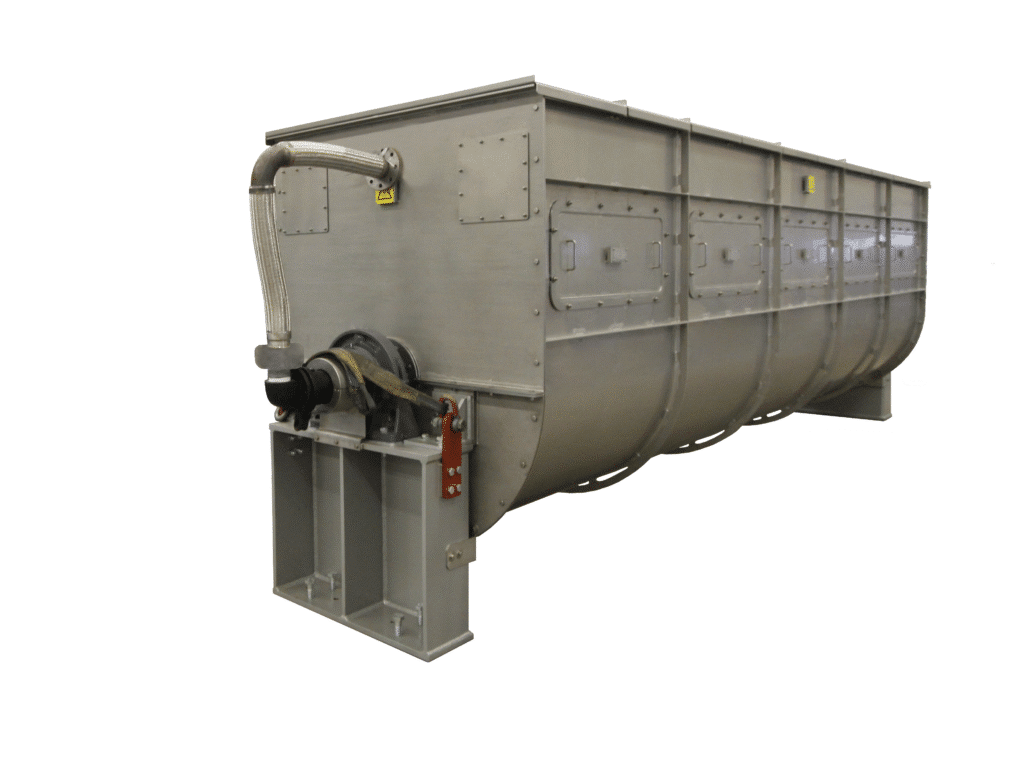

The Tummers Simon Dryers Technology Tubular Dryer and Cooler are also designed for drying and cooling metal powders, offering a continuous process that delivers consistent results with low energy consumption and maximum safety.

Whether you’re processing atomized powders, recovered metal dust, or by-products from metalworking, our technology ensures optimal moisture control and temperature uniformity.

Contact our specialists to discuss your metal powder drying application.

Why choose the Simon Tubular Dryer for metal powders?

Continuous operation

Enables 24/7 drying and cooling of metal powders.

Energy-efficient design

Uses indirect steam heating and condensate recovery for maximum heat efficiency.

Low dust, high safety

Indirect drying means minimal air flow, reducing explosion risk and dust generation.

Compact setup

The Tubular Dryer can be mounted directly above the Tubular Cooler for space efficiency.

Material flexibility

Available in carbon steel, stainless steel, or special alloys to match product requirements.

Economical and scalable

More cost-effective than batch drying, suitable for small to large-scale production.

How it works

The Tubular Dryer operates with a steam-heated tube bundle rotating inside a stationary casing.

A series of lifters pick up the material and cascade it over the heated tubes while it’s conveyed along the length of the machine.

- The steam inside the tubes provides indirect heat for drying.

- A small amount of sweep air removes the evaporated moisture.

- Rotary joints at each end handle steam inlet and condensate collection.

Once dried, the metal powder exits the dryer at an elevated temperature and is fed directly into the Tubular Cooler, which uses water as a coolant.

Together, they form an efficient, closed, and energy-recovering drying system.

Don’t see your specific material listed?

We have a large database of test results and offer laboratory trials for new materials.

Typical Applications

Our Tubular Dryer and Coolers are ideal for a wide range of metal and powder processing applications, including:

- Wet atomized metal powders

- Powders from product recovery or filtration systems

- Metal dusts and residues from machining

- Iron, copper, aluminum, and nickel powders

- Powders used in automotive, additive manufacturing, and sintering industries

- Recovered metal powders for recycling and reuse

Don’t see your specific material listed?

We have a large database of test results and offer laboratory trials for new materials.

Performance & safety advantages

The Tubular Dryer is an indirect-contact dryer, relying on dry saturated steam instead of hot air.

This design provides significant safety and efficiency advantages:

- Lower dust explosion risk – minimal air flow means fewer airborne particles.

- Smaller dust filters – less air to filter, reducing operating cost and maintenance.

- Closed system – minimal contamination and consistent product quality.

- Condensate recovery – returns steam condensate to the boiler for energy reuse.

- Uniform drying – precise control of temperature and residence time ensures consistent moisture levels.

Why work with us?

100+ years

experience in drying technology.

Engineered

Machines designed for dust control, energy efficiency, hygiene and clean-label compatibility.

Support

From testing in our lab to installation and after-sales service.

Sustainable

Efficient steam use, minimal waste and high product yield.

Frequently asked questions

It provides continuous, indirect drying that eliminates the need for high airflow. This reduces dust creation, explosion risks, and energy consumption while ensuring precise moisture control.

Suitable for a wide range of ferrous and non-ferrous powders, including iron, copper, aluminum, nickel, and alloy powders, as well as recovered metal dust and atomized feedstock.

Tubular Dryers use steam as the heating medium, recovering condensate and saving energy.

Hot air dryers waste heat through exhaust air and require large dust filters, making the tubular system more efficient and safer.

Yes. Because the air volume inside the dryer is very small, the potential for dust-laden air and ignition sources is greatly reduced.

Absolutely. The gentle tumbling action and indirect heat transfer make the Tubular Dryer suitable for delicate and dense metal powders alike.

Depending on your product’s chemical and thermal properties, dryers can be manufactured from carbon steel, stainless steel, or nickel/chrome alloys.