Harness tomorrow’s resources today; innovative drying for algae and seaweed across food, cosmetics, medicines and more.

Algae and seaweed are rapidly becoming “products of tomorrow.” They’re extremely versatile and used in food, animal and aquaculture feed, cosmetics, pharmaceuticals, textiles and packaging materials. To unlock their full potential, efficient and specialised drying industrys are key.

At Tummers Simon Dryers Technology, we deliver high-performance drying and washing systems tailored for all types of seaweed and algae, enabling you to elevate your raw material into high-value final products.

Interested in drying algae or seaweed in your process? Contact our team today to explore your next step.

Why choose our systems for algae & seaweed?

Tailored machine industrys – For example

-

- Washing stage: Our Tummers Destoner/Washer has been deployed for seaweed washing (capacity up to 50 t/h) in real-world installations.

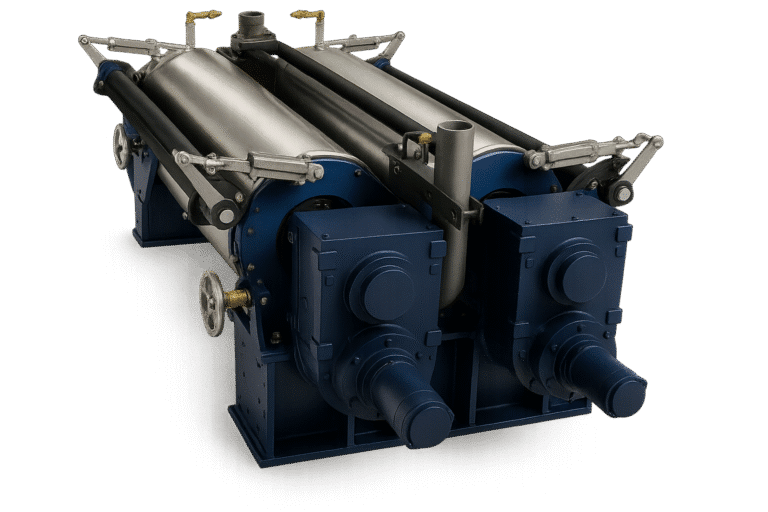

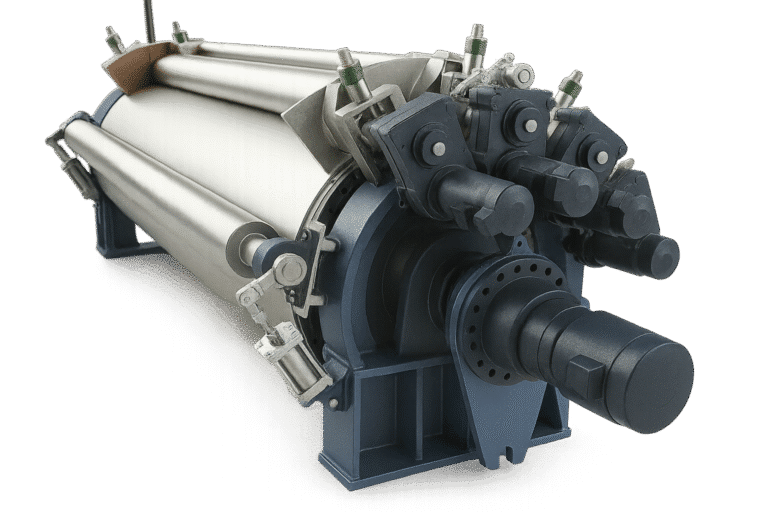

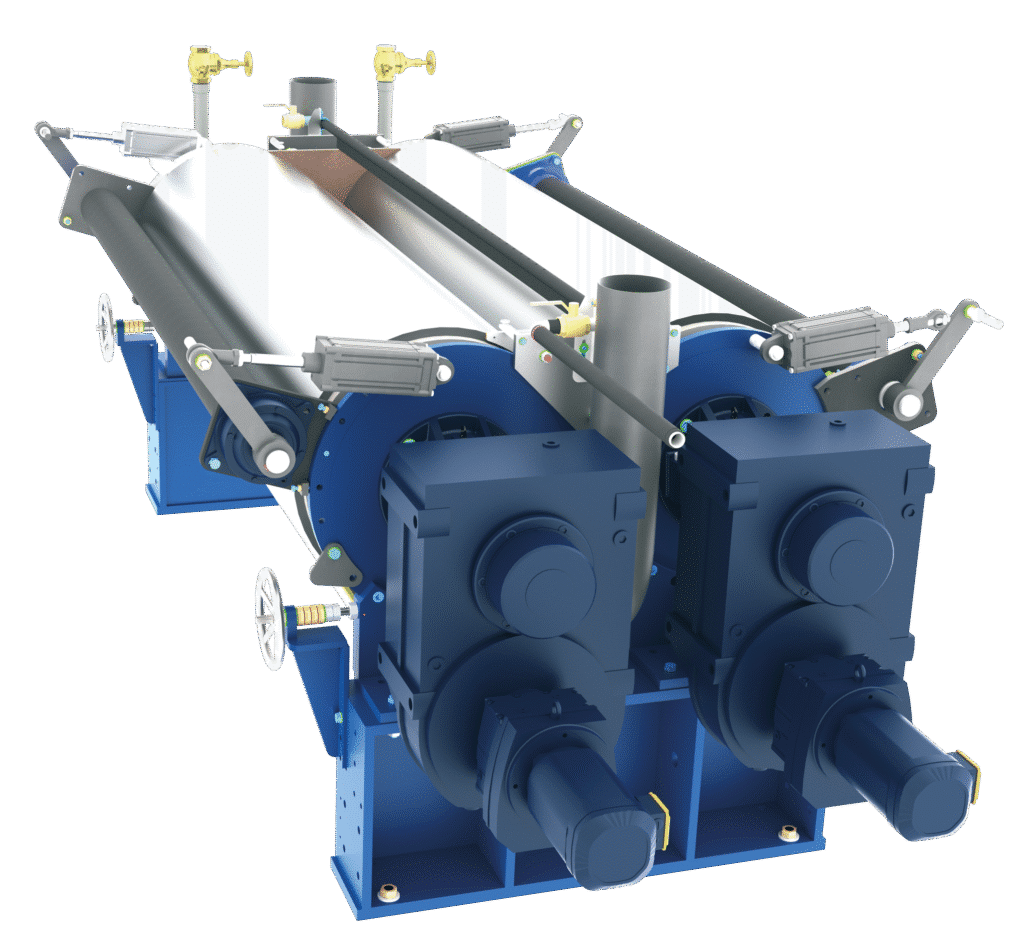

- Drying stage: Our Drum Dryers (double & single) from the Simon Dryers line are built for indirect, low-dust drying of algae & seaweed biomass.

Versatility

Suitable for whole seaweed, algae slurries or paste, used for food, feed, pharma, cosmetics and material applications.

Nutrient preservation

With correct drying technology, key functional compounds (proteins, lipids, pigments) are preserved, supporting quality in high-value markets.

Sustainable processing

Our industrys align with circular-bioeconomy goals: transforming marine biomass into usable ingredients while minimising waste and energy consumption.

Lab-to-production support

Many drying tests are already on record for algae; we offer laboratory trials and full-scale industrys.

How it works

1. Washing & preparation – Raw seaweed is cleaned and de-stoned using our dedicated Washer System, removing sand, shells and impurities prior to drying.

2. Machine selection & drying –Depending on the product, either our Single-Drum Dryer: a thin layer is applied, moisture evaporated rapidly and product removed as flakes, or our Double-Drum Dryer: material introduced between two drums, film thickness adjusted, moisture evaporated from both sides.

3. Product handling – Dried flakes or powders are collected, milled or screened, cooled and packed.

4. R&D & optimization – In our lab we test materials, drying behaviour and final product specs, so you launch with confidence.

Don’t see your specific material listed?

We’ve processed a wide variety of fruit & vegetables; let’s discuss your unique feedstock and test it in our laboratory.

Typical applications

- Dried seaweed flakes or powders for food & snack applications

- Algae biomass for feed & aquaculture; high protein, fat and pigment content

- Cosmetic & pharmaceutical raw materials derived from seaweed/ algae extracts

- Marine-based materials for textiles, packaging or biomaterials

Don’t see your exact product type listed?

We have extensive test data and can perform a full laboratory drying trial for your specific feedstock.

Performance and expertise

Our combined offering of 100 + years’ experience in drying technology, along with real-world installations for seaweed washing and drying, positions us as a trusted partner for marine biomass processing. From pilot trials to full mechanised lines, we’re here to help you unlock value from your algae.

Why work with us?

100+ years

experience in drying technology.

Engineered

Machines designed for dust control, energy efficiency, hygiene and clean-label compatibility.

Support

From testing in our lab to installation and after-sales service.

Sustainable

Efficient steam use, minimal waste and high product yield.

Frequently asked questions

Yes. Our flexible systems accept a wide range of algae and seaweed types. We tailor the washing and drying process to suit each material’s behaviour and moisture content.

Algae and seaweed have high moisture content, rich bioactive compounds and often require gentle handling to preserve function. Indirect steam or drum drying ensures consistent final moisture without damaging valuable nutrients.

Absolutely. We conduct lab-scale drying trials, analyse final quality metrics (proteins, pigments, lipids, moisture) and then scale up the process for production.

Yes. Our Destoner/Washer machine has already been used for seaweed washing at commercial capacity.

Flakes, powders or granulates; depending on your downstream process. We advise on the best format for your market (food, feed, cosmetics or materials).

By converting seaweed into stable, high-value ingredients you reduce waste, utilise marine biomass effectively and align with circular economy goals.