Efficient drying of brewery by-products; transforming waste into valuable feed ingredients.

Brewing produces a range of by-products rich in nutrition and fibre — and our drying technology helps you turn them into valuable resources.

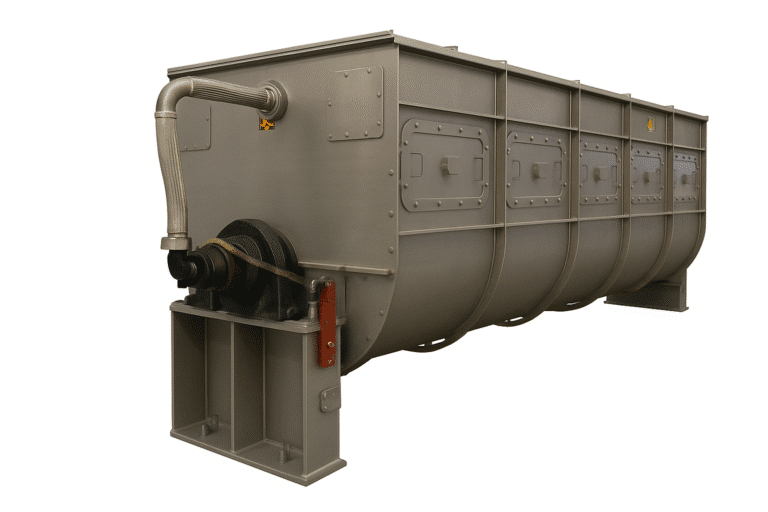

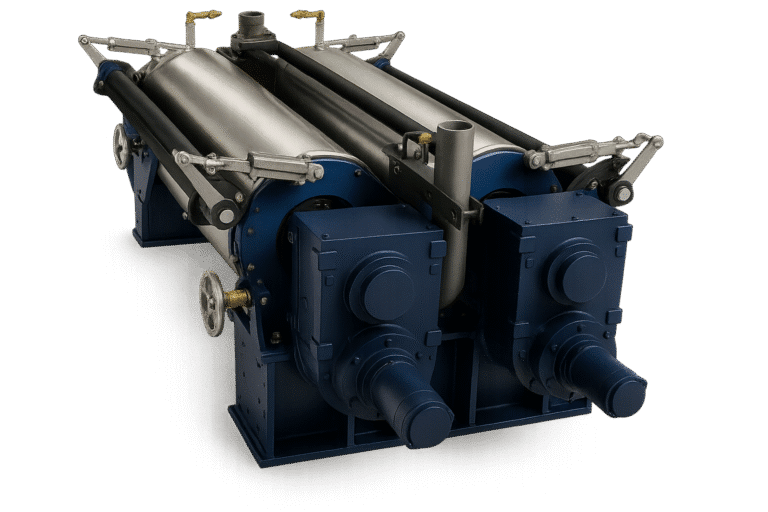

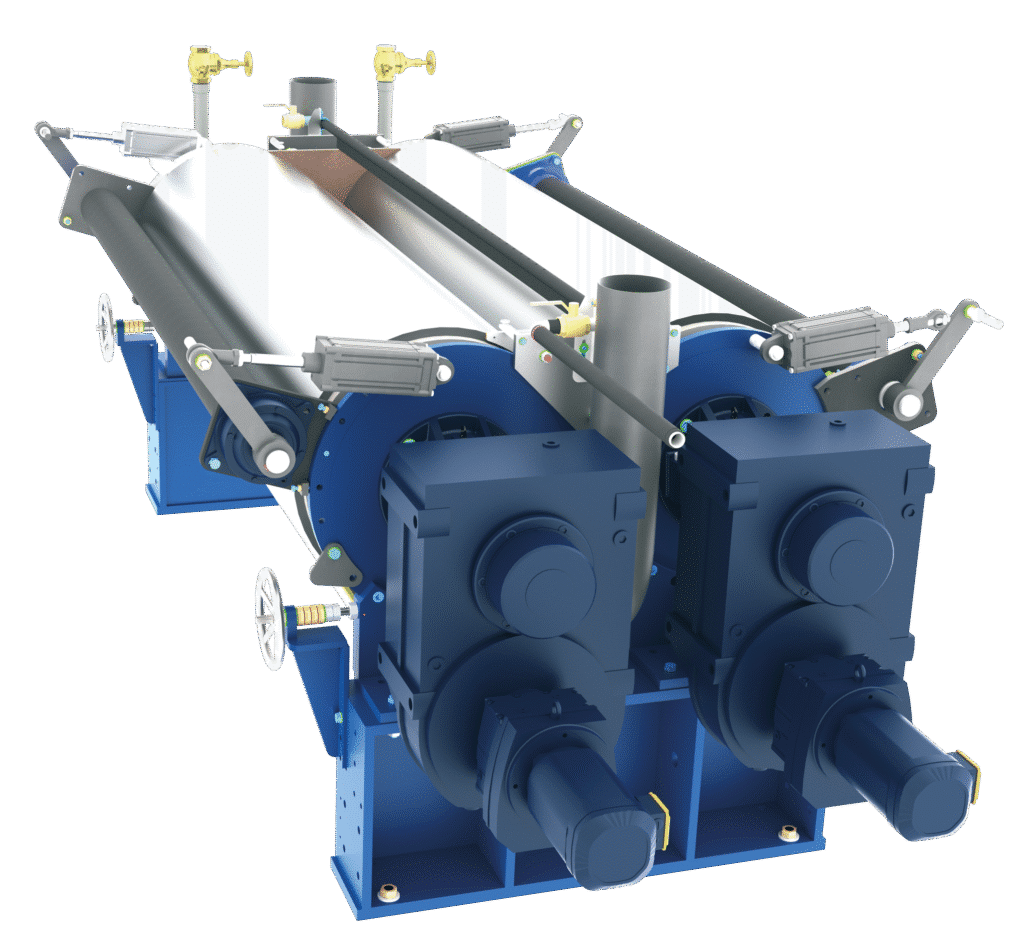

At Tummers Simon Dryers Technology, we provide Tubular Dryers and Coolers for spent grain, and Double Drum Dryers for spent yeast, delivering efficient, sustainable drying for the brewing industry worldwide.

Let’s talk about your feed-drying process — our team is ready to help.

Why choose our brewery drying systems?

Tailored machine industrys

-

- Tubular Dryer & Cooler for spent grain and brewers’ residues.

- Double Drum Dryer for spent yeast and other slurry-based by-products.

Sustainable & efficient

Reduce waste and energy use while recovering valuable proteins and fibres.

Safe, hyienic operation

Closed, indirect drying with minimal dust and odour.

Proven performance

Built on 100+ years of drying experience in food and brewing industries.

From lab to full-scale

We can test your material in our laboratory and scale up confidently to production.

How it works

1. Feed preparation – Wet by-products such as spent grain or spent yeast are pre-filtered or dewatered.

2. Drying process –

- On a Double Drum Dryer, Ideal for spent yeast, applying a thin layer between steam-heated drums, removing moisture efficiently and producing uniform flakes.

- In a Tubular Dryer, Indirect steam-heated system dries spent grain to the desired moisture content for feed use.

3. Collection & cooling – Dried product is cooled, milled or flaked, and ready for use as animal feed or nutrient supplement.

4. Quality testing – Our lab tests drying curves, moisture levels, and product behaviour to help you achieve consistent results.

Don’t see your by-product listed?

We have extensive data from brewery trials and can perform new lab tests for your specific materials.

Typical applications

- Spent grain drying → using Tubular Dryer & Cooler

- Spent yeast drying → using Double Drum Dryer

- Malt dust or other brewery residues

- Protein-rich feed ingredients

- By-product reuse for animal nutrition

- Yeast extract powder production

Don’t see your by-product listed?

We have extensive data from brewery trials and can perform new lab tests for your specific materials.

Built for performance and sustainability

Our drying systems are designed to help breweries meet modern sustainability goals: reducing waste, cutting energy use, and generating new value streams.

Whether you’re operating a large brewery or a specialty craft plant, our modular systems ensure efficiency, reliability, and consistent product quality.

Why work with us?

100+ years

experience in drying technology.

Engineered

Machines designed for dust control, energy efficiency, hygiene and clean-label compatibility.

Support

From testing in our lab to installation and after-sales service.

Sustainable

Efficient steam use, minimal waste and high product yield.

Frequently asked questions

Our Tubular Dryer & Cooler offers efficient indirect drying, achieving precise moisture content for animal feed while maintaining nutritional integrity.

We use a Double Drum Dryer; applying a thin layer of yeast slurry between steam-heated drums, producing uniform dried flakes suitable for feed or further processing.

We recommend pre-concentrating or dewatering the feed using filtration or centrifugation. This reduces energy use and improves drying performance.

By converting brewery by-products into reusable materials, you lower disposal costs, reduce waste, and support circular production in the brewing industry.

Yes. Our dryers use indirect steam heating and closed designs, minimising dust, contamination and odour for food- and feed-safe production.

Absolutely. You can send us your spent yeast or grain, and we’ll run tests in our laboratory or pilot-scale dryers to find the best configuration.