Efficient, reliable drying for feed ingredients; from by-products to premium pet nutrition.

Animal nutrition plays a vital role in global food production. At Tummers Simon Dryers Technology, we design drum and tubular drying industrys that transform animal by-products and protein sources into safe, shelf-stable, high-value feed ingredients.

Our systems are trusted worldwide for fish food flakes, spent yeast, animal proteins, and pet food formulations built for efficiency, hygiene, and consistent quality.

Let’s talk about your feed-drying process — our team is ready to help.

Why choose our drying technology for feed & pet food?

Machine flexibility

-

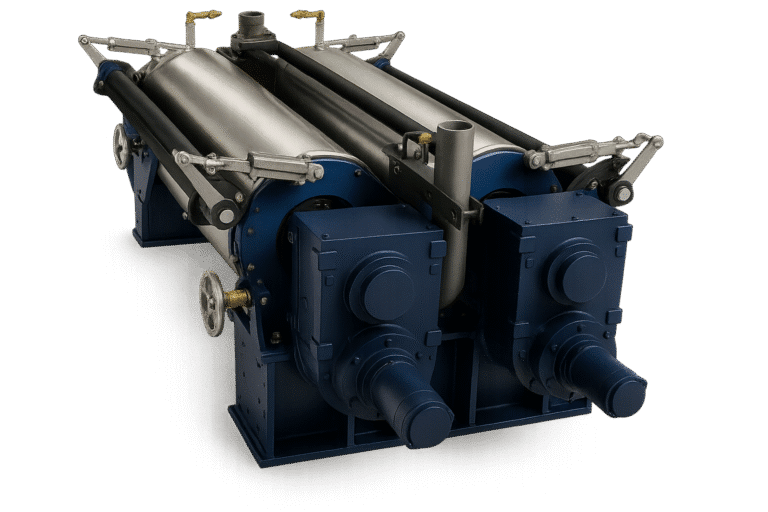

- Use our Double-Drum Dryer for fish food flakes and heat-sensitive proteins.

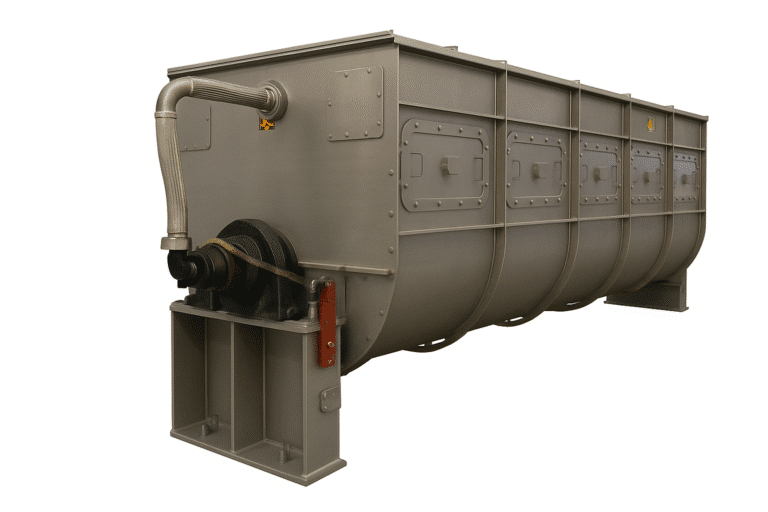

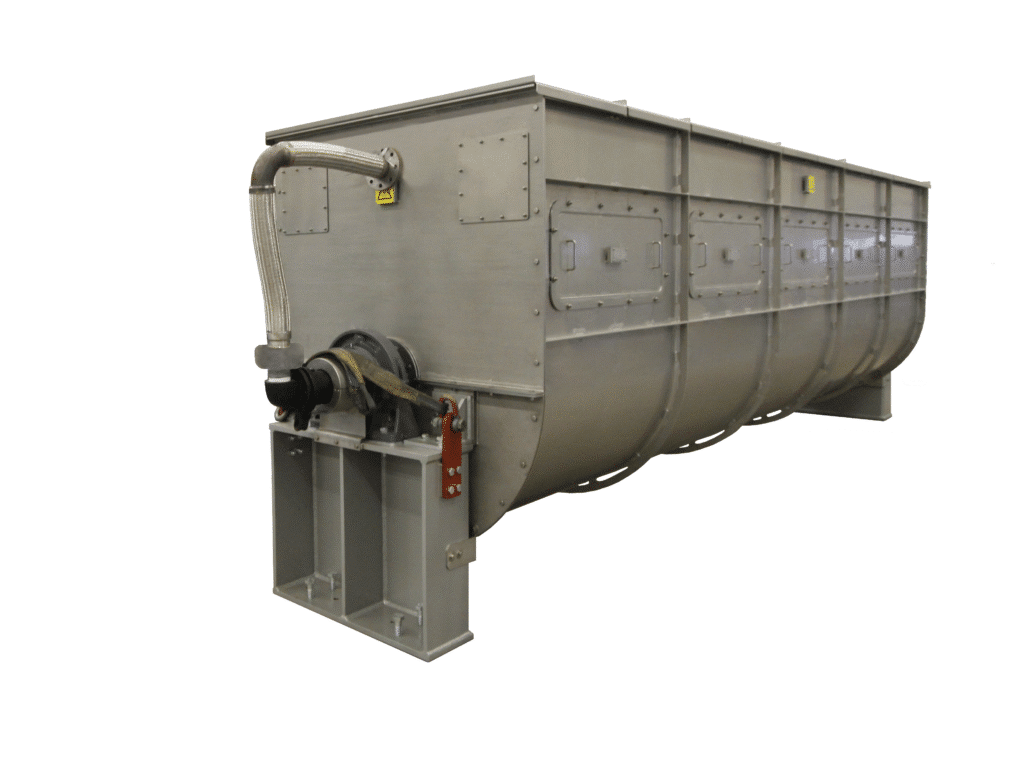

- Use our Tubular Dryer for spent grains and other by-product materials. spent yeast and other by-product materials with higher moisture content.

Energy-efficient operation

Low steam-to-evaporation ratio and condensate heat recovery.

Consistent, safe product

Uniform drying ensures stability, palatability, and nutritional integrity.

Hygienic design

Built for feed-grade and food-grade production environments.

Lab-to-production support

We maintain a fully-equipped laboratory and extensive test data for confectionery applications, ensuring you scale confidently.

How it works

1. Preparation & feeding – The wet feedstock (e.g. yeast slurry, fish mix, or protein by-product) is pre-filtered or dewatered.

2. Drying process –

- On a Double-Drum Dryer, a thin film is applied and dried into flakes with controlled texture and protein retention.

- In a Tubular Dryer, In a Tubular Dryer, materials like spent grains are dried indirectly with steam, ensuring low dust and energy efficiency.

3. Collection & cooling – Dried material is removed, cooled, milled or granulated for further formulation.

4. Quality testing – Samples are analysed for moisture, density, and rehydration performance in our laboratory.

Don’t see your exact product listed?

We’ve processed a wide variety of feedstocks.

Send us a sample and our lab technicians can simulate your process and provide data before scale-up.

Typical applications

- Fish food flakes and aquatic feed bases

- Spent yeast drying for feed & brewing by-products

- Animal proteins & bone meal

- Pet food ingredients and treats

- Algae & seaweed for natural feed additives

- Feed by-products from starch or brewery processes

Don’t see your exact product listed?

We’ve processed a wide variety of feedstocks.

Send us a sample and our lab technicians can simulate your process and provide data before scale-up.

Why work with us?

100+ years

experience in drying technology.

Engineered

Machines designed for dust control, energy efficiency, hygiene and clean-label compatibility.

Support

From testing in our lab to installation and after-sales service.

Sustainable

Efficient steam use, minimal waste and high product yield.

Frequently asked questions

Our Double Drum Dryer delivers thin, uniform flakes with precise texture and protein preservation — ideal for fish and aquatic feed.

Yes. Our Tubular Dryers are perfect for spent brewers or distillers’ grains, and other wet by-products, converting them into stable feed ingredients. Our Drum Dryers are perfect for spent yeast.

It provides clean, energy-efficient heat transfer with minimal dust and odour; reducing environmental impact while maintaining product quality.

Absolutely. Our feed laboratory allows you to test small batches, study drying curves, and evaluate product behaviour before investing in full-scale production.

All our dryers are designed with enclosed systems, vapour extraction, and easy-clean access to meet feed- and food-grade standards.

Yes. The indirect heating design ensures gentle drying and prevents scorching, even for materials with sensitive fats or proteins.

With steam-based indirect heating, condensate recovery, and low air sweep, our dryers operate with an energy ratio as low as 1.2 kg steam per kg of water evaporated; far more efficient than hot-air systems.

Performance you can trust

With over 100 years of experience, our dryers have become a benchmark in feed processing, combining high capacity, energy efficiency, and robust engineering.

Each system is tailored to your feed formulation and production needs, from pilot testing to industrial installation.