Small-scale drying for big ideas; innovation starts here.

Our Laboratory Dryers are designed for research, pilot testing, and educational applications across the food, starch, and pharmaceutical industries.

They’re the perfect bridge between lab-scale experimentation and full-scale production, allowing you to test, optimize, and innovate with confidence.

Ready to experiment? Get in touch with our team for a lab setup that fits your goals.

Why choose the Laboratory Dryer?

Flexible configurations

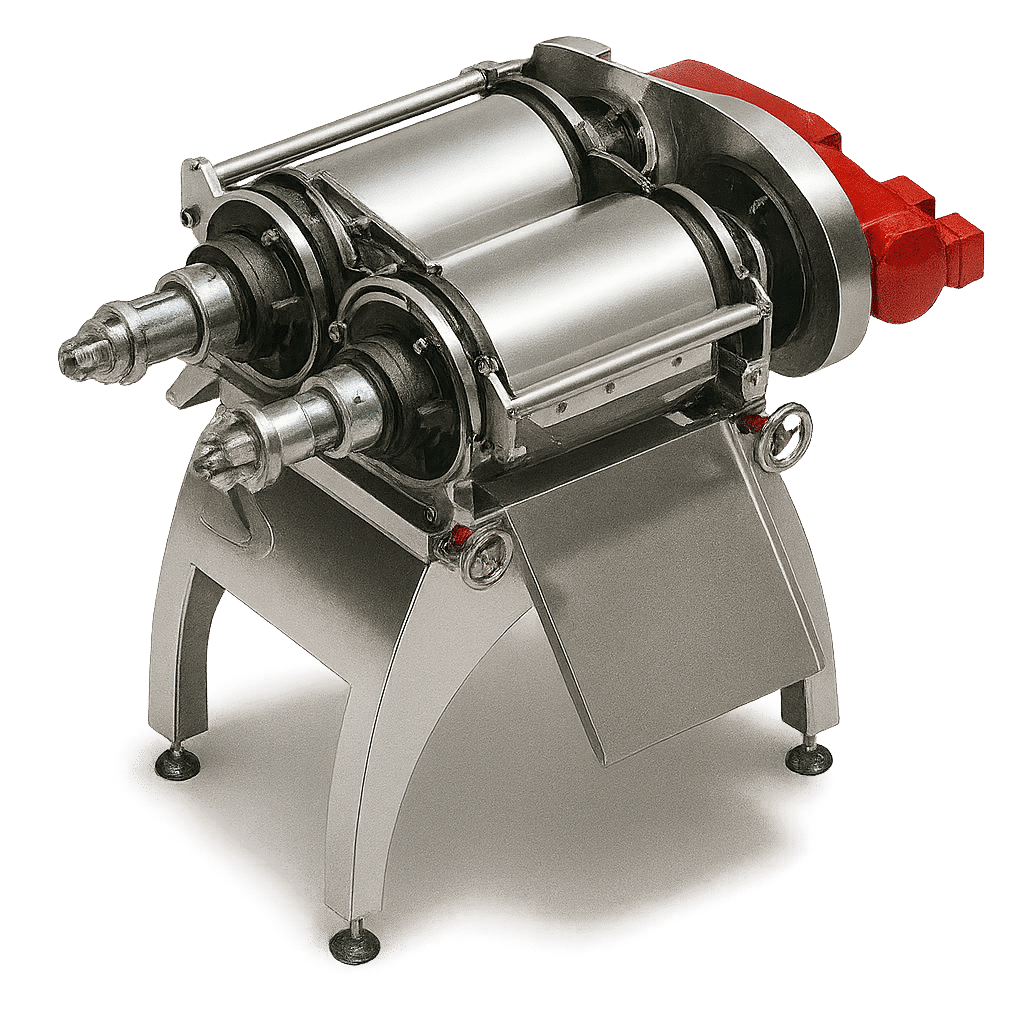

Our drum application is available single or double drum dryers, and flakers.

Ideal for R&D and education

Supports product development, recipe testing, and training.

Steam-heated or water-cooled

Adaptable for both drying and flaking applications.

Quick conversion

Switch between drying and flaking setups in minutes.

Compact & ready-to-run

Fully assembled units, easily connected to your existing services.

Sustainable design

Built for efficient use of steam, water, and energy.

How it works

The Laboratory Dryer replicates full-scale drying processes on a smaller, controllable platform.

Each unit comes equipped with precise controls for temperature, rotation, and film thickness, making it ideal for testing starches, fruit mixes, proteins, or pharmaceutical products.

Our pilot-scale drum dryers can handle small production runs or generate larger sample batches for market trials, bridging the gap between R&D and commercial scale-up.

Applications

- Food & starch research – test drying behaviour for new or modified starches

- Pharmaceutical development – controlled drying for powders, actives and blends

- Education & training – ideal for universities and research institutes

- Pilot production – produce sample flakes or powders for customer trials

- Sustainability testing – explore energy-efficient drying with minimal waste

Need to test your material?

Our laboratory and pilot units are available for trials. So explore performance before scaling up to production.

The power of small-scale innovation

At Tummers Simon Dryers Technology, we believe innovation begins at the laboratory level.

That’s why every dryer we offer, from tubular to drum, is also available in a lab or pilot version.

So whether you’re developing new ingredients, teaching process engineering, or optimizing an existing recipe, we’ve got the right tool for you.

Why work with us?

100+ years

Experience in drying technology.

Engineered

Machines designed for dust control, energy efficiency, hygiene and clean-label compatibility.

Support

From testing in our lab to installation and after-sales service.

Sustainable

Efficient steam use, minimal waste and high product yield.

Frequently asked questions

We offer tubular dryers, single and double drum dryers, and flakers — all designed for lab and pilot-scale operation.

Perfect for R&D teams, universities, and companies with in-house laboratories.

They’re widely used in food, starch, chemical, and pharmaceutical research.

Yes. With a quick configuration change, the same unit can switch between drying and flaking modes.

Lab dryers can be steam-heated for drying or water-cooled for flaking, depending on your process requirements.

Absolutely. Our R&D lab is open for material testing, process trials, and recipe optimization.

We’ll help you translate lab results into full-scale performance

They do. Our pilot systems are designed to mirror industrial dryers in terms of heat transfer, rotation, and product handling, so your data scales reliably.

Everything from starches, fruit and vegetable pulps, algae, proteins, milk derivatives, to chemical and biological suspensions.